When it comes to custom packaging, getting the box dimension right is one of the most important steps—yet it’s often overlooked. A box that’s too tight might damage your product, while one that’s too loose can feel unprofessional and waste materials. In this guide, we’ll walk you through how to measure your product accurately and factor in space for inner trays, padding, and structural design. Whether you’re packaging a toy, a book, or a set of delicate items, this step-by-step approach will help you estimate the perfect box size with confidence.

How to Set the Correct Packaging Box Dimension?

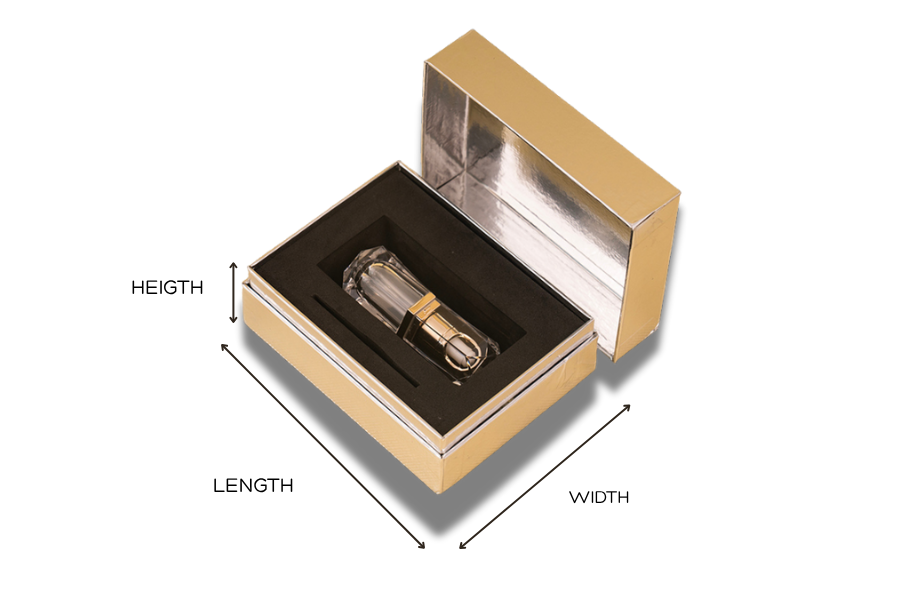

While it’s easy to simply place a product into a box without much thought, quality packaging goes far beyond that. Much like how clothing enhances and protects us, a well-designed box serves both to present and to safeguard the product inside. When budget allows, it’s worth giving your product the best possible packaging experience. The packaging box dimension is primarily determined by the size of the product itself, and then slightly adjusted based on any additional protective materials you include within the box.

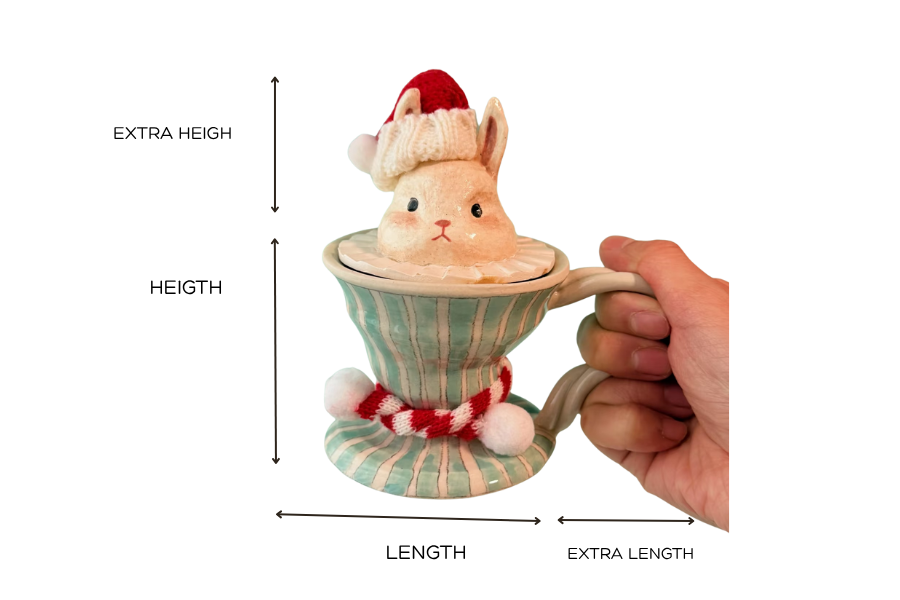

1. Does Your Product Have an Irregular Shape?

Is there any part of your product that sticks out—like handles, tails, sharp corners, or decorative elements? Always measure the outermost points. For example, if your cup is 5 cm tall but has a bunny on the lid, the actual height might be 6 cm. You need to use that full dimension, not just the body of the cup, when planning your packaging box dimension.

2. Do You Need Protective Cushioning?

Is your product fragile or breakable, like ceramics or plastic toys? If so, you should reserve 5–10 mm of extra space on all sides to allow for padding or foam. This space acts as a buffer against shock during shipping and handling and must be added to your overall packaging box dimension.

3. Will You Use an Inner Tray or Insert?

Do you need an insert—such as EVA, molded pulp, or plastic—to hold your product securely in place? These inserts take up space, especially in height. If you’re placing one tray above and one below your product, remember to add the combined thickness (e.g. 0.8 cm top and bottom = 1.6 cm) into your final packaging box dimension calculation.

4. Are You Packing More Than One Product in a Box?

Do you plan to put multiple units in the same box? If yes, think about how they’ll be arranged—side by side, stacked, or layered. The total layout and any internal dividers should also be factored into your packaging box dimension planning.

How Different Box Structures Affect Packaging Box Dimensions?

When designing packaging, most people start by measuring the product itself. While this is the essential first step, it’s not the only factor that influences the final packaging box dimension. The type of box structure you choose plays a big role in how much space is actually needed. Different structures add layers, folds, overlaps, and reinforcements that directly affect the box’s internal and external measurements.

Below are some common box types and how each of them affects sizing.

1. Rigid Lid & Base Box

This is a classic two-piece box with a separate lid and base. It’s often used for gift boxes, toy packaging, and premium products. Because the lid typically overlaps the base, you’ll need to account for the lid depth when calculating height. Also, if you’re using an inner tray, that too needs to fit snugly inside the base—making precision important.

Size impact:

Final box height = product height + insert (if any) + lid overlap

Requires more precise internal sizing to ensure the lid fits cleanly

2. Drawer Box

Drawer-style boxes consist of an inner tray that slides out from an outer sleeve. To ensure smooth movement, the outer sleeve must be slightly larger than the tray—usually by 2–3 mm on each side. This extra space must be added to your packaging box dimension, especially in width and height.

Size impact:

Tray must fit snugly, but not tightly, into the sleeve

Final outer size = inner tray size + material thickness + sliding clearance

3.Magnetic Closure Box

Book-style boxes open like a hardcover book and often feature a magnetic closure. This structure typically requires extra space on the spine and cover flap. Additionally, the inner area that holds the product must be inset, which slightly reduces usable interior space.

Size impact:

Spine and flap widths need to be added to overall width

Magnetic closure can influence thickness and material layering

4.Corrugated Mailer Box

Corrugated boxes are widely used for eCommerce and shipping. Their flaps, folds, and double-layer walls take up internal space, meaning the packaging box dimensions must include the material thickness (typically 1.5–2 mm per wall). Ignoring this will make your product fit too tightly—or not at all.

Size impact:

Final outer size = internal product size + 2x material thickness per dimension

Especially important for bulk packaging and mailing

5. Shoulder Neck Box

This premium box structure includes a middle “neck” that fits between the lid and base, creating a seamless, elevated appearance. The neck height can vary based on design preferences and must be added as a separate layer in height calculations.

Size impact:

Neck height + base depth + lid coverage = final height

Often adds 1–2 cm in height, depending on neck design

Conclusion

Choosing the right box isn’t just about style—it directly affects how your product fits, ships, and presents. Always keep in mind that your packaging box dimension is the result of both product measurements and box structure. Getting this right from the beginning can save you time, reduce costs, and ensure a better unboxing experience.

If you’re unsure how to adjust your measurements based on structure, feel free to reach out or use our simple box size calculator coming soon to this site!