When people buy a new pair of shoes, what usually happens to the shoe box? Some keep it for storage, while others throw it away after a short time. However, this question should not only be considered by consumers. For brands and sellers, it raises a more important issue: how can a custom shoe box be designed to better support shoe storage and long-term reuse? A well-designed custom shoe box is no longer just a disposable package. It can protect the shoes, organize storage, and even become a reusable part of the customer’s daily life adding value beyond the initial purchase. As a professional supplier specializing in custom shoe box solutions, this article will explore how thoughtful design, structure, and materials can help solve common storage challenges and turn a shoe box into a practical, reusable packaging solution for modern brands.

Common Custom Shoe Box Structure

Analysis of Mainstream Shoe Box Structures in the Market

| Shoe Box Type | Typical Material | Structural Complexity | Transportation & Storage | Material Cost | Retail Store Suitability | E-commerce Suitability |

|---|---|---|---|---|---|---|

| Lid & Base Box (Rigid Two-Piece Box) | Greyboard | High | Not foldable; bulky for shipping; requires more storage space | High | Excellent | Average |

| Drawer Shoe Box (Slide Box) | Greyboard | High | Not foldable; bulky; higher logistics cost | High | Excellent | Good |

| Foldable Shoe Box | Corrugated Board(E-flute / B-flute) | Low | Foldable; efficient for transport and storage | Medium to Low | Good | Excellent |

1. Lid and Base Shoe Box (Two-Piece Shoe Box)

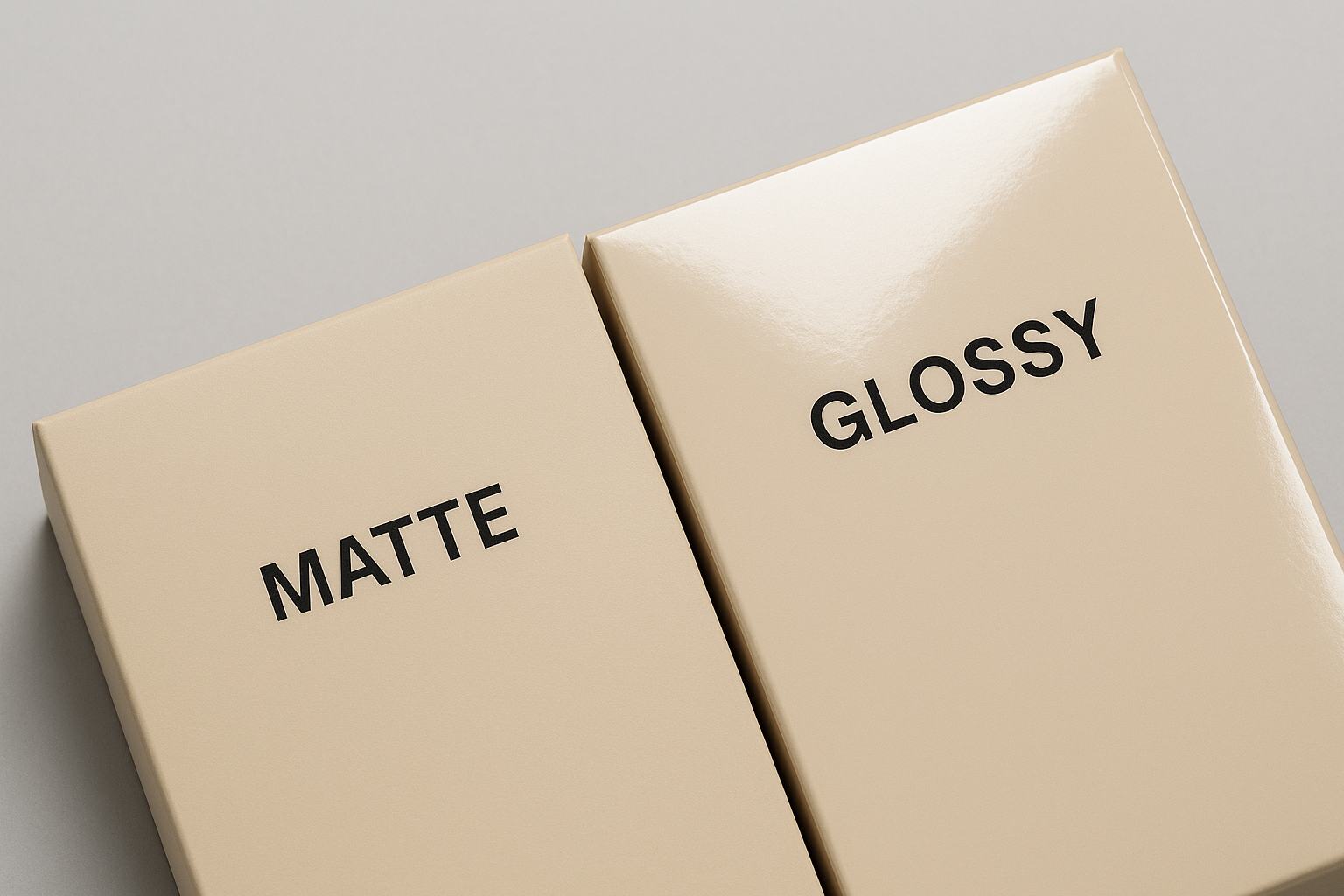

A lid and base shoe box is one of the most common structures used in custom shoe box packaging. This type of shoe box consists of two separate parts—the lid and the base—rather than a single integrated structure. Because it is not one-piece, the pressure distribution during transportation is uneven. Manufacturers often compensate for this by using thicker paperboard to improve impact resistance. However, this solution significantly increases the overall weight of the package, leading to higher shipping costs and making it less environmentally friendly.

In addition, while thicker materials help reduce external impact, they do not completely prevent shoe deformation caused by pressure during transit. On the positive side, lid and base shoe boxes perform relatively well in moisture protection, offering a basic level of protection against humidity.

2. Drawer Shoe Box

Structurally, a drawer style shoe box is similar to a lid and base box, but with an added outer sleeve either foldable or rigid into which the inner box slides. This structure makes the custom shoe box more expensive in both production and transportation compared to traditional two-piece boxes. However, it offers better overall protection for the shoes. Because the inner box is fully enclosed by the outer sleeve, drawer shoe boxes provide improved resistance to pressure and external impact.

More importantly, during actual shipping and storage, this fully wrapped structure helps isolate the shoes from moisture and environmental interference, making drawer style shoe boxes a popular choice for premium and sneaker brands that prioritize protection and presentation.

3.Flip-Top Shoe Box Packaging

Flip-top shoe boxes are designed as a one-piece structure, which helps reduce material usage and lowers production costs to some extent. Compared to traditional rigid boxes, this structure also takes up less space during storage and transportation. In the age of e-commerce, damaged and deformed shoe boxes during delivery have negatively affected the brand image of many online footwear brands. Flip-top custom shoe box packaging has significantly improved this issue by offering better structural integrity and durability throughout the shipping process.

However, flip-top shoe boxes have a clear limitation when it comes to moisture resistance. Without additional protective solutions—such as inner coatings, moisture barriers, or desiccants—their performance in humid environments is relatively weak and requires supplementary measures.

Common Shoe Box Sizes

| Shoe Type | Recommended Internal Size (L × W × H) | Explanation & Typical Use |

| Men’s Standard Shoes / Sneakers | 13.0–14.0 × 8.0–9.0 × 4.0–5.0 in(≈ 33–36 × 20–23 × 10–13 cm) | Ideal for most men’s sneakers, athletic shoes, casual shoes. |

| Women’s Shoes / Flats / Heels | 12.0–13.0 × 7.0–8.0 × 4.0–5.0 in(≈ 30–33 × 18–20 × 10–13 cm) | Common for women’s flats, low heels, and standard casual shoes. |

| Children’s Shoes | 8.0–10.0 × 5.0–6.0 × 3.0–4.0 in(≈ 20–25 × 13–15 × 8–10 cm) | Compact sizing for children’s footwear. |

| Boot Box (Ankle / Mid / High) | 14.0–15.0 × 10.0–12.0 × 5.0–6.5 in(≈ 35–38 × 25–30 × 12–16.5 cm) | Taller boxes suitable for boots and high-top shoes. |

| Sandals / Flip-Flops / Minimal Shoes | 11.0–12.0 × 7.0–8.0 × 3.0–4.0 in(≈ 28–30 × 18–20 × 8–10 cm) | Shallow boxes optimized for lightweight footwear. |

Note: These sizes reflect common internal box dimensions used by global footwear brands and packaging suppliers. Actual sizes vary by shoe design, sole height, and brand preference.

How a Custom Shoe Box Can Be More Sustainable

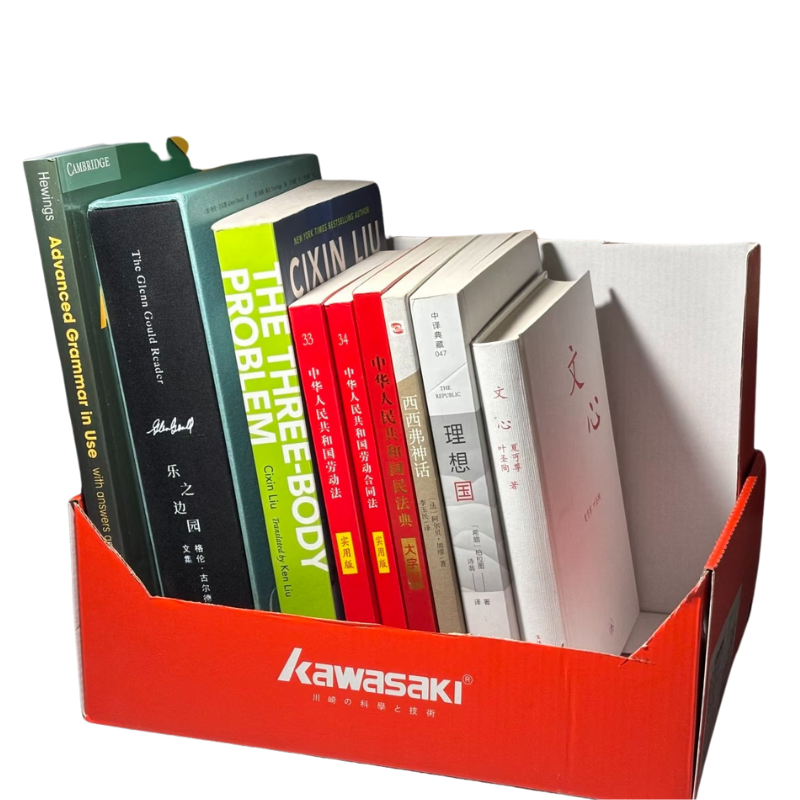

Encouraging consumers to reuse packaging is one of the most effective ways to improve sustainability. A well-designed custom shoe box can go beyond basic protection and become a practical storage solution for everyday use.

One approach is to add adjustable dividers inside the shoe box. These dividers allow consumers to reposition the internal layout according to different shoe types, creating flexible and suitable storage spaces. This adaptability significantly increases the likelihood that the shoe box will be reused rather than discarded.

In addition, functional elements such as zippered pockets, inner pads, or compartments can be incorporated into the custom shoe box design. These features make it easier for consumers to store and organize shoe-related accessories, including socks, shoe care products, insoles, or cleaning tools. As a result, the shoe box evolves from simple packaging into a multifunctional storage solution.

Another sustainable design strategy is to consider modular or detachable shoe box structures. For example, a shoe box can be designed to separate into two independent sections—one dedicated to shoe storage, and the other transformed into a functional item such as a small stool, a storage container, or even a shoe display platform. This type of design not only enhances the practicality and functionality of the custom shoe box, but also increases consumer interest, emotional engagement, and motivation for repeated reuse.

Ultimately, sustainability in packaging is not only about materials, but about creating value that lasts beyond the initial purchase.

Conclusion

A well-designed custom shoe box is no longer just a container for transportation. From box structure and sizing to reusability and sustainability, every design choice influences how long the packaging remains useful after the purchase. By selecting the right shoe box type, optimizing dimensions for storage and protection, and integrating features that encourage reuse, brands can significantly extend the lifecycle of their packaging. This not only reduces waste, but also enhances the overall customer experience and reinforces brand value in everyday use.

Sustainable packaging is not defined solely by materials, but by thoughtful design that balances protection, functionality, and long-term practicality. When a custom shoe box becomes something consumers want to keep and reuse, it transforms from disposable packaging into a lasting part of the product experience.

For brands exploring custom shoe box solutions, understanding these design considerations is the first step toward packaging that delivers value well beyond the point of sale.