UV coating is a finishing technique in which a clear or colored varnish is applied to the surface of printed packaging to create a glossy, striking, and dimensional look. As consumers increasingly seek premium, personalized, and visually engaging packaging, UV coating has become one of the most popular ways for brands to elevate the unboxing experience. Reports also indicate that the use of UV finishes in packaging will continue to grow significantly in the coming years.

However, because of its unique characteristics, UV coating must be used carefully. When applied to certain types of custom boxes or combined with other finishing methods, conflicts may occur, leading to unintended visual or structural effects. That’s why designers and packaging engineers need to understand the limitations of UV coating and avoid common pitfalls when preparing artwork files or planning the final production.

1.Types of UV Coating Techniques

In today’s rapidly evolving packaging industry, there are numerous UV coating options available. Among them, Spot UV and Reverse UV are the most commonly used, offering both high efficiency and cost-effectiveness. For luxury packaging, more specialized techniques like Holographic UV are often applied. Although these advanced methods involve more complex processes and higher costs, they deliver outstanding visual and tactile effects that truly elevate the overall packaging experience.

Spot UV

Spot UV is applied only to selected areas such as specific graphics or text. By creating a sharp contrast between the glossy coated sections and the surrounding matte paper, it highlights key details and enhances both visual impact and tactile dimension. This is the most widely used UV finish in packaging.

Flood UV

Flood UV covers the entire surface of the packaging box with a uniform layer of UV varnish. It is primarily used to protect printed graphics, improve scratch resistance, and give the box a consistent high-gloss finish. Matte flood UV is also available, offering full-surface protection while minimizing reflections. Due to its higher cost, it is typically used more selectively.

Reverse UV

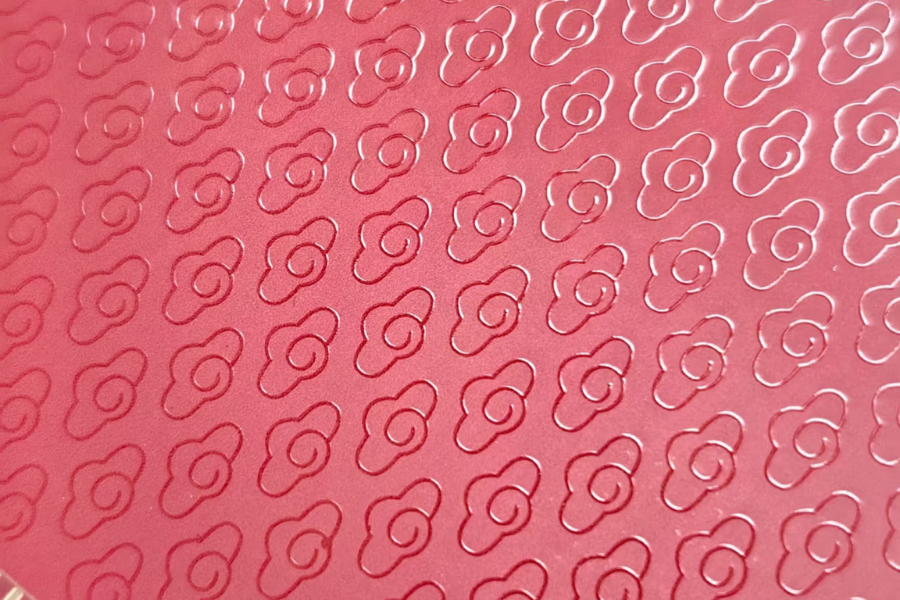

Reverse UV is achieved by first applying a full layer of UV varnish across the entire sheet (or a specific area), followed by printing a textured UV base coating on top where needed. Because the two UV formulations naturally repel each other, the second layer forms a matte or frosted texture, while the base layer remains glossy. This creates an artistic contrast of “matte texture on a glossy background,” making it especially stunning when paired with metallic paperboard such as gold or silver card stock.

Frosted UV

Frosted UV uses a special matte UV varnish that cures into a non-reflective, lightly textured surface similar to frosted glass. It is typically used on smooth paper to create a subtle, white-tinted matte appearance with a finer texture compared to traditional matte lamination.

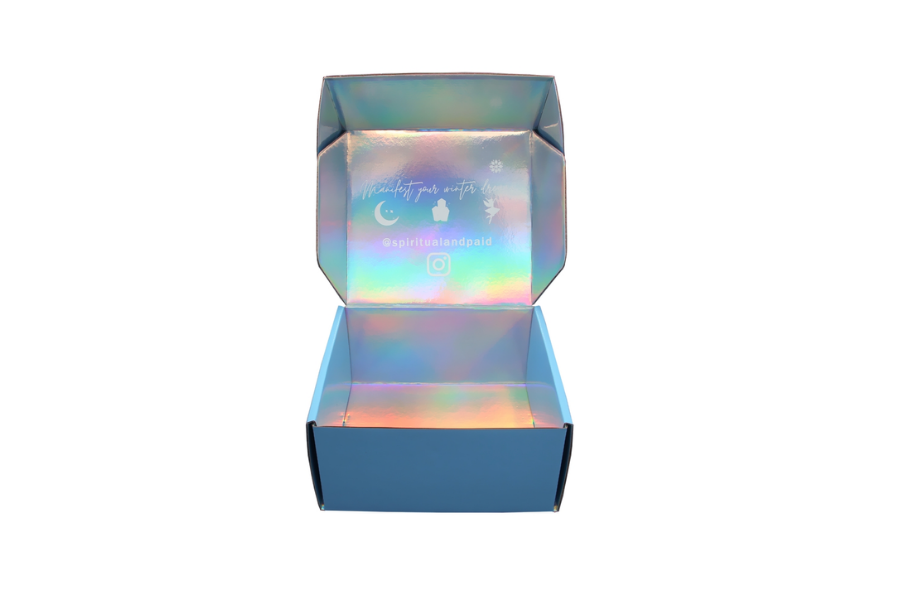

Rainbow Iridescent UV

Rainbow UV incorporates special pigments or pearlescent powders into the UV layer, allowing the coated areas to shift colors like a rainbow when viewed from different angles. This highly eye-catching effect is often used in luxury packaging to create a vibrant, dynamic visual impression.

2.Key Considerations When Applying UV Coating on Packaging Boxes

When using UV coating in packaging production, selecting the right file resolution is essential. Because UV finishes support high-resolution printing, the source artwork must meet the corresponding requirements: screen printing UV should not be lower than 200 dpi, while offset UV needs at least 300 dpi to ensure crisp and accurate results.

The core strength of UV coating lies in its ability to create strong contrast. For this reason, it performs best on darker-colored packaging, where the glossy effect becomes more visually prominent. UV also pairs naturally with matte surfaces—the contrast between matte and gloss makes the UV details stand out even more. If the box is not originally matte, applying a matte lamination or anti-glare finish beforehand can significantly enhance the final UV effect.

Another important consideration is controlling the UV coverage area, as the cost increases proportionally with the amount of UV applied.

UV coating should not be placed on top of foil stamping areas, as the two processes conflict. The glossy UV layer prevents hot foil from adhering properly. While UV can technically be applied over foil, it is generally not recommended—both techniques serve the purpose of highlighting specific elements, and combining them often results in redundancy rather than improvement.

When preparing artwork, avoid using gradients in Spot UV areas. Since Spot UV is meant to emphasize specific shapes or elements, gradients weaken the contrast, causing the UV effect to look inconsistent and lose its intended highlight function.

Finally, UV coating should not be used on very small text or thin lines. Excessively fine details may appear blurred or unclear once coated. As a practical guideline, text should be no smaller than 7 pt, and line thickness should be at least 1.5 pt to ensure clean, sharp results after UV curing.

3.UV Coating Trends in Packaging Boxes

As brands continue to compete for shelf impact and unboxing appeal, UV finishing is evolving from a simple gloss effect into a strategic branding tool. One major trend is precision UV detailing, where brands use ultra-fine patterns, micro-textures, and controlled gloss levels to create a luxury look without relying on metallic foils or overly complex structures. This approach delivers refinement while keeping production efficient.

Another growing direction is matte–gloss contrast design, which has become a signature technique for premium packaging. When combined with soft-touch or matte lamination, UV accents pop even more, helping brands emphasize key elements such as logos, icons, and storytelling graphics. This trend perfectly aligns with the rise of minimalist packaging—simple layouts but highly tactile finishes.

Sustainability is also influencing the future of UV finishing. More suppliers are adopting eco-friendly UV coatings with lower VOCs, improved curing efficiency, and better recyclability. Water-based and LED-UV technologies are gaining traction, allowing brands to achieve the same high-gloss results while reducing environmental impact.

Finally, the demand for customization at scale is pushing UV finishing into digital territory. Digital UV spot coating and 3D UV printing offer faster turnaround, short-run flexibility, and personalized effects without the need for physical plates. This makes it easier for small and medium brands to experiment with limited editions, seasonal packaging, and targeted campaigns.

In short, the future of UV finishing lies in precision, sustainability, tactile design, and digital innovation.It gives packaging boxes not just a shiny surface, but a stronger story and deeper brand value

Frequently Asked Questions about UV Coating on Packaging Box

Is UV coating environmentally friendly?

Modern UV coatings—especially LED-UV and low-VOC formulations—are becoming more eco-friendly. They cure faster, generate less waste, and are compatible with recyclable paperboard, making them suitable for brands with sustainability goals.

What Is the Difference Between Matte UV and Regular Matte Finishing on Packaging Boxes?

Matte UV = textured, premium, high-definition matte effect.

Regular matte finishing = smooth, subtle, budget-friendly matte look.

On what surfaces does UV coating work best?

UV performs best on dark-color matte surfaces, as the contrast becomes more visible. If the packaging isn’t originally matte, adding a matte lamination or anti-gloss coating first will significantly enhance the UV effect.

What’s the Difference Between UV Coating and Embossing on Packaging Boxes?

Use UV when you want shine, contrast, or detail enhancement.

Use embossing when you want strong tactile impact and a premium, dimensional finish.