When designing paper-based packaging—whether it’s custom boxes, retail wraps, or luxury inserts—the choice of paper material matters more than you might think. One key decision? Whether to use coated or uncoated paper. Each gives your packaging a different look, feel, and impact on your brand identity.

In this article, we’ll explore the difference between coated and uncoated paper for packaging, and help you choose the right one for your next product launch.

What Is Coated Paper in Packaging?

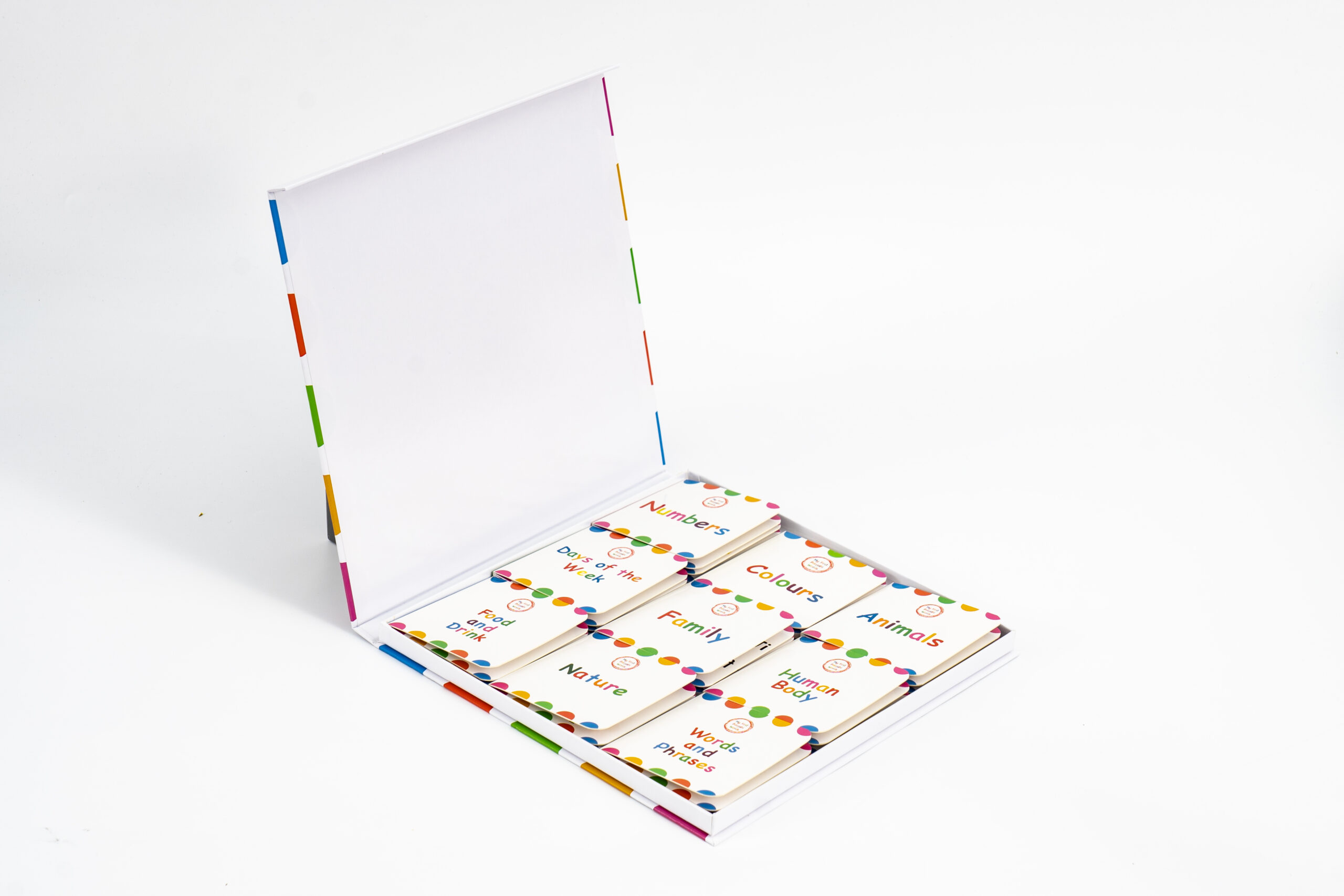

Coated paper has a smooth finish and a glossy or matte coating, perfect for packaging that requires sharp images, vibrant colors, and a premium retail look. Think of the shiny surface on high-end cosmetics boxes or technology packaging—those are usually printed on coated paper.

Best suited for:

Printed gift boxes

Color-rich folding cartons

Product labels or sleeves

Retail display packaging

High-end paper bags

Coated vs Uncoated Paper: Which Looks Better for Packaging?

| Feature | Coated Paper | Uncoated Paper |

|---|---|---|

| Visuals | Sharp, photo-like finish | Soft, muted tones |

| Feel | Smooth, modern, glossy | Textured, warm, organic |

| Ink behavior | Ink sits on top (vivid) | Ink absorbs in (matte look) |

| Eco perception | Less natural-looking | Seen as more sustainable |

| Writable? | No / smudges | Yes – great for labels, notes |

Packaging Design Tip: Match Paper to Brand Personality

Luxury or tech packaging? Use coated paper for a high-gloss professional image

Natural, handmade, or eco-brand? Go with uncoated paper to express authenticity

Need packaging people can write on (e.g. gift messages)? Uncoated is ideal

Whether you’re launching a premium product line or rolling out an eco-friendly brand, understanding the difference between coated and uncoated paper in packaging design helps you make better choices for your visuals, your sustainability goals, and your customer experience.